BUSINESS

EnvironmentENVIRONMENT

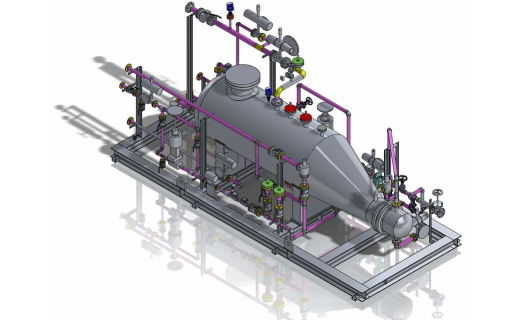

UreAm® (UREA-AMMONIA GENERATING SYSTEM)

Purpose & Features

It is a system that generates ammonia by using urea solution and supplies it to the nitrogen oxide (NOx) reduction system (SCR) of power plants, incinerators, and plants (petrochemical). It has excellent efficiency and safety.

Principle

Ammonia gases produced by applying heat energy to the Urea solution eliminate nitrogen oxides (NOx) by reaching with the nitrogen oxides that cause air pollution and converting them to N2 and H2O harmless to the human body

Prospects and expected effects

- This system prevents explosions and leaks by improving safety issues with ammonia, a hazardous substance.

- This system minimizes air pollutant emissions by using non-hazardous urea solution.

DeNOx System Comparison

| Method using ammonia tanks | Category | Method using UreAm® |

|---|---|---|

| Procedure |

|

|

| Power Plants, Incinerators, Plants (Petrochemicals) | Place of Use | Power Plants, Incinerators, Plants (Petrochemicals) |

| Applied to most of domestic | Application | Applied to most of America and Europe |

| Ammonia solution or Anhydrous ammonia | Substance used | Urea solution |

| 9% (Ammonia solution) or 99.5% (Anhydrous ammonia) |

Ammonia concentration | 25 ~ 30% (Average 28%) |

| Classified as hazardous material (Need to appoint a hazardous materials manager) |

Handling and care | Classified as non-hazardous

materials (No need to appoint a hazardous materials manager) |

| Ammonia Tank, Ammonia Pump, VAporizer |

Compositional facilities | Urea solution tank, Urea solution, Pump, UreAm® Skid System, Air Mixer |

| Fixed selected ammonia flow rate (Automatic operating method) |

Operating method | Ammonia flow rate adjustable (Automatic operating method) |

| Need a certain area as a dangerous

goods facility (Retaining wall installation required) |

Intallation method | No regulation with

non-hazardous equipment (No retaining wall installation required) |

Patent - Ammonia Generating System

Trademark - UreAm®

SCR (SELECTIVE CATALYST REDUCTION)

It is an air pollution prevention facility that reduces nitrogen oxides (NOx) emitted from combined cycle power plants, cement manufacturing plants, petrochemical plants, and etc. Since 2006, the use of SCR in domestic power plants has become mandatory, and demand is expanding worldwide in line with the strengthening of environmental pollution regulations.

PYROLYSIS SYSTEM

SUNGSAN’s Pyrolysis System incorporates the latest continuous pyrolysis technology. Continuous supply system, continuous rotary pyrolysis system, continuous slagging system, continuous cooling system, odor removal system, continuous exhaust recycling system, continuous smoke removal system, PLC automatic control system, etc. The entire pyrolysis process runs in a completely enclosed environment and at a very high level of automatic control, eliminating the need for manual work for feed and slagging. Automated and mechanical processes make your work environment completely secure and clean.